THE

BLACK EDITION™ ENGINE OVERHAUL PROCESS:

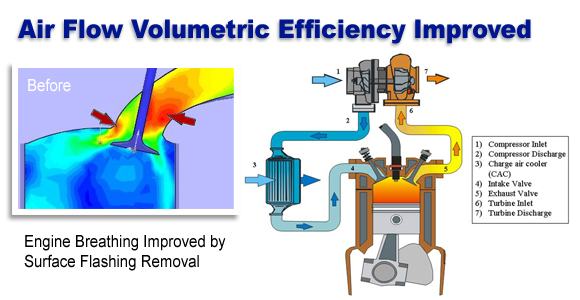

AIR FLOW/VOLUMETRIC

EFFICIENCY IMPROVED

Watch the video ! (movie length - 1.5 minute) Watch the video ! (movie length - 1.5 minute)

By matching the cylinders VE airflow characteristics a better balanced engine airflow is obtained providing for improved acceleration, smoothness, fuel efficiency and power.

When cylinders arrive at Victor Aviation they are airflow tested to determine their individual flow characteristics. It is quite often found that airflows may vary, as much as 15%-20% between them, meaning that if installed on an engine they would produce an unbalanced power output. As airflow varies from cylinder to cylinder so does individual cylinder horsepower. This imposes an unequal strain on the engines crankshaft and crankcase, and reduces engine horsepower. |

|

An engine is a machine that converts fuel energy to rotating motion, which is commonly measured as horsepower. In the engine, gasoline is added to air as it passes through the carburetor (or fuel injectors) on its way to the cylinder. This mixture is then burned in the cylinder, creating heat, which creates pressure. This pressure pushes the piston down in the cylinder to turn the crankshaft.

Imagine that you have a 100 cubic inch single cylinder engine. On the intake stroke, the piston moves to the bottom of the cylinder and creates a volume that is 100 cubic inches. The fuel/air mixture that fills this volume is what will be used to create the power.

Now imagine that this engine has some type of restricted intake, such as an air filter, carburetor or injector and an intake manifold. With this configuration, the intake manifold has a fairly good vacuum. In this case, even though the piston pulls a volume of 100 cubic inches into the cylinder, it is not atmospheric air. Here, you have the 100 cubic inches of the vacuum from the manifold.

Volumetric efficiency (VE) is used to describe the amount of fuel/air in the cylinder in relation to regular atmospheric air. If the cylinder is filled with fuel/air at atmospheric pressure, then the engine is said to have 100% volumetric efficiency. On the other hand, super chargers and turbo chargers increase the pressure entering the cylinder, giving the engine a volumetric efficiency greater than 100%. However, if the cylinder is pulling in a vacuum, then the engine has less than 100% volumetric efficiency. Normally aspirated engines typically run anywhere between 80% and 100% VE.

Regardless of whether you have a normally aspirated or turbocharged engine improving the engines Volumetric Efficiency will provide improved power. When an engine is throttled back to a low cruise power setting, engines are starving for air and any improvement in the cylinders Volumetric efficiency will greatly affect aircraft performance. Customers have often commented that after installing a Black Edition II engine in their aircraft that they were able to maintain an equivalent “before and after” airspeed WITH LOWER POWER SETTINGS and lower fuel consumption on many models.

Volumetric efficiency is also reduced if it is found that the induction system or cylinder intake area has any casting irregularities (surface flashings) that obstruct the smooth flow of air. Using a specially designed Air Flow Test Bench used by Victor Aviation we can detect these abnormalities by simulating a “wind tunnel” for measuring the air entering and exiting the cylinder. By carefully removing any unwanted surface flashings we improve the cylinders Volumetric Efficiency and improve power distribution so that all cylinders will breathe more efficiently. The more fuel/air that gets into the cylinder, the more power the engine will produce and better fuel efficiency is obtained.

This FAA Accepted Special Procedure used at Victor Aviation does not reduce the original cylinder port wall thickness or alter the original cylinder design. Only deviations from the original manufacturer’s casting design are removed.

back |