|

Cryogenic Tested, Ultimate High Performance Engine Building |

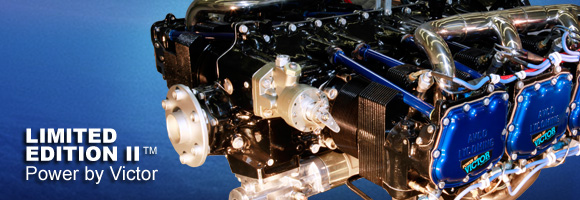

A “Power By Victor” LIMITED EDITION II™ Engine Overhaul is the absolute ultimate in the Engine Overhaul Industry. All Special Engine processes incorporated in the Black Edition II Overhaul are Included and further advanced with Cryogenic Processing Technology included.

Critical engine parts are Cryogenically NDT Tested at -300 degrees Fahrenheit, using a Liquid Nitrogen LN2 atmosphere, in a state-of-the-art Computer Controlled Vacuum Insulated Processing Chamber. Using this specialized process enables Power By Victor technicians to further determine the quality and overall durability of engine parts. As parts are subjected to these test procedures any parts that may have inconsistent or irregular internal grain structures can be identified using this process. Only parts that meet the dimensional stability criteria of a LIMITED EDITION II™ engine will be installed in the engine.

NASA started cryogenics as a science back in the mid 1960’s. Their scientists noted that many of the materials used in spacecraft were some how improved once they were subjected to the hot and cold of space. They started to study why and helped to start this emerging field of Cryogenic Processing. Today Cryogenic Processing is widely used in the space program, Aerospace, Nascar and other advanced engine programs.

As a result of Cryogenic Processing and other unique state-of-the-art finishing processes included, Victor Aviation can now provide on a LIMITED EDITION II™ Engine, an extended Limited Workmanship Warranty for 5 years, pro-rated up to 10 years or TBO.

| Certificated FAA Part 91 Operations Engine Coverage |

Effective 1/01/11 |

LIMITED EDITION II™

Express Limited Workmanship Warranty |

10 YEARS COVERAGE / TBO

100% Coverage for 60 Months or TBO whichever occurs first.

Coverage prorates after 60 months up to 120 months.

ECI Cylinders 5 Year Warranty Optional |

|

High Performance, Flowed & Balanced, Electrostatic Powdercoated Product,

Reduced Vibration, Enhanced Reliability |

Flying an aircraft with a "Power by Victor"™ Black Edition II™ engine will bring you the smoothest, most efficient and reliable performance obtainable from a piston engine. Customers from around the world have been flying reliably behind our engines since 1977. Not only does the engine provide high performance and superior smoothness but also added value. Field overhauled or production-built engines frequently depreciate in value an average of 30%-40% when installed. The Aircraft Bluebook Price Digest officially recognizes the added value when a "Power By Victor"™ Black Edition II™ Engine is installed, with up to a 100% added value to aircraft.

Not only has the general pilot population discovered the added value, but original aircraft manufacturers have had their new “zero-time” engines converted to "Power By Victor"™ Black Edition II™ Engines. There is no Supplemental Type Certificate, or Parts Manufacturing Approval required by the FAA, and requires only a log book entry for the work performed. All work is accepted under our FAA operating specifications of Victor Aviation.

With a Black Edition II™ Overhaul we begin by meeting the required parts replacements as provided from the original manufacturer and then include our additional Black Edition II™ Special Overhaul Processes. The finished result is an engine with maximum engine Performance and Power, Significant Vibration Reduction, Improved Reliability and Increased Aircraft Value.

Victor Aviation is proud that they have improved quality and performance standards in the industry and always stays one step ahead of the imitators. No other aircraft engine supplier can match the added value of a "Power By Victor"™ Black Edition II™ engine or our consistent reputation for superior quality, improved engine performance and worldwide customer support.

A Black Edition II™ Engine Overhaul is a Proprietary Trademarked Overhaul Process created by Victor Aviation Service Inc. View

a Black Edition!(2 MB)

| Certificated FAA Part 91 Operations Engine Coverage |

Effective 1/01/11 |

BLACK EDITION II™

Express Limited Workmanship Warranty |

7 YEARS COVERAGE / 750 HOURS

100% Coverage for 24 Months or 750 hours whichever occurs first.

Coverage prorates after 24 months up to 84 months. |

|

Engine built to Factory Specifications for zero time, fits and clearances

|

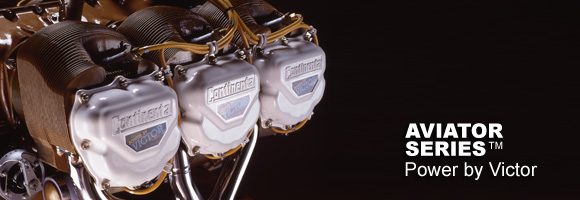

A “Power by Victor” AVIATOR SERIES Engine Overhaul incorporates precision workmanship and machining procedures similar to or better than virtually all other engine over haulers. The benefits of the Aviator Series are improved safety, enhanced reliability, and maximum endurance at a level of cost that can satisfy just about any pilots operating budget.

All Power By Victor AVIATOR SERIES Engines are assembled to factory Zero-Time New Fits and Clearances, and include parts required to satisfy the 100% parts replacement for normal wear requirements for overhaul.

Engines come with Rebuilt Cylinders and engines are balanced to Factory Specifications.

| Certificated FAA Part 135 Operations Engine Coverage |

Effective 1/01/11 |

AVIATOR SERIES

Express Limited Workmanship Warranty

|

2 YEARS COVERAGE / 480 HOURS

100% Coverage for 12 Months or 480 hours whichever occurs first.

Coverage Prorates after 12 months up to 24 months. |

|

Customer Customization and Ultimate High Performance |

A Power-By-Victor Gold Edition II™ Engine is designed for the high performance, experimental aircraft builder or owner who wants the benefits of a zero-time factory engine that will perform like a Power-By-Victor engine.

We start by taking a “zero-time” factory new Textron Lycoming or Teledyne Continental Motors engine and testing the engine in our specially engineered load cell for thrust velocity, vibration harmonics, and complete engine performance characteristics. Using a spectrum analyzer and piezoelectric accelerometers, our technicians can determine the frequencies and amplitudes of internal moving parts to determine real-time parts motion balancing prior to engine disassembly.

The engine is then completely disassembled, inspected and the unique Power-By-Victor processes used in Victor’s Limited Edition II™ Engine, are applied to the “zero-time” factory new Textron Lycoming or Teledyne Continental Motors engine.

When we have completed the Power-By-Victor engine procedures, the engine is then re-tested in our engine load cell to assure that we have extracted the maximum performance potential from the engine without sacrificing engine reliability or safety. By comparing the incoming and final engine test runs, we are able to document what engine characteristics have changed.

Engines can be finished to customer specifications and custom powder coat colors are available. For experimental aircraft applications, we work closely with the aircraft builder and have several engine performance modifications and processes available.

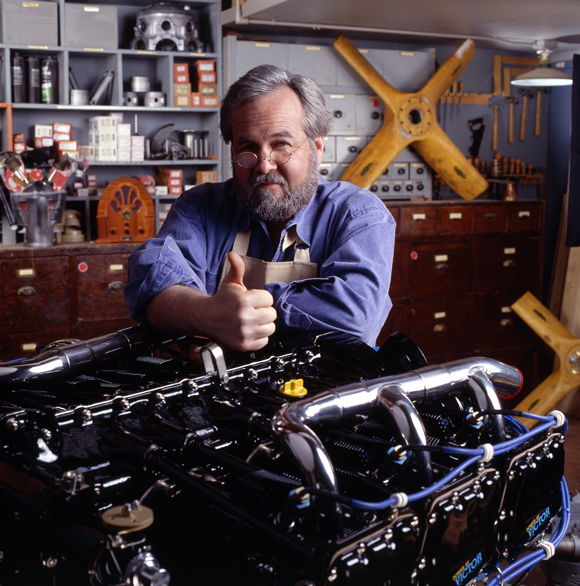

Come see why we are “The Best In The Business”

Victor Aviation is world renowned as the leader in piston aircraft engine rebuilding technology. Come visit our facilities in Palo Alto, California and meet the highly skilled A.S.E. Certified Master Machinists who build the “Best Engines in the Business”. We are located just 30 minutes south of San Francisco Airport and with prior arrangements we would be happy to pick you up to tour our facilities.

Victor Aviation specializes in engines for the following applications:

| Aerostar 601,602,700 |

| Beechcraft 33, 35, 36, 58, 60 |

| Cessna 177, 182, 185, 206, 207, 210, 303, 310, 320, 335, 340,402, 404, 414,421 |

| Cirrus SR20, SR22 |

| Columbia 300, 400 |

| Edge 540 |

| Glasair III |

| Lancair 320, 360, ES, Legacy, IV, IV-P |

| Mooney M20, 231, 252, TLS, Bravo, Ovation, Acclaim |

| Piper PA-23, 24, 28, 30, 31, 32, 34, 44, 4 |

| Robison R22, R44 Helicopters |

| Seawind 300C |

| Velocity SE, XL, TXL |

|