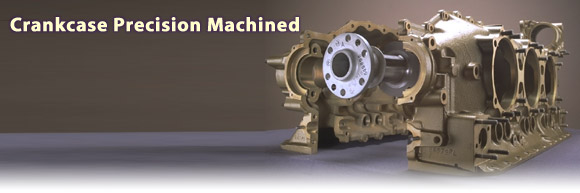

THE

BLACK EDITION™ ENGINE OVERHAUL PROCESS:

CRANKCASE PRECISION

MACHINED

The crankcase of an engine not only provides structure and

rigidity to the engine but also keeps major moving parts in alignment.

This is important, because even slight misalignments in such critical

components as the connecting rods, main bearings, or cylinders can easily

result in premature wear or engine failure.

The crankshaft must be held exactly on the engine's geometric

centerline if adverse stresses on rods and bearings are to be avoided.

Cylinder decks heights, the horizontal distance from the crankcase centerline

to the cylinder hold down area, must be the same for all cylinders so

that all pistons have identical cylinder travel to provide for equal compression

ratios. Proper machining of the crankcase crankshaft bore, will ensure

that the centerline axis of the crankshaft will be true and parallel to

the deck planes and will eliminate any unwanted stress on the crankcase

or other moving engine parts. Precision machining of the case bore also

will ensure the proper pinch fit for the engine's main bearings, allowing

for proper oil pressure and improved engine life.

Through the use of sophisticated lapping and boring machinery, all "Power

By Victor"™ engine crankcases are machined to the utmost in

quality control to allow for longer engine life, reduced friction and

improved power. After the crankcase is machined, it goes through a special

metal stress relieving process called "normalizing" to ensure long crankcase

life. Crankcases are alodine- treated and finally electrostatic powdercoated

to ensure durable, long-lasting corrosion protection. Again, this is one

of Victor's unique special processes that adds that extra touch of quality

control to every "Power By Victor"™ Black Edition™

Engine.

back |