|

Scott Crossfield

Edition: World’s Most Reliable

Piston Engine?

Employing cryogenic technology,

the Scott Crossfield Edition engine

may be the most reliable in

general aviation.

By Bill Cox

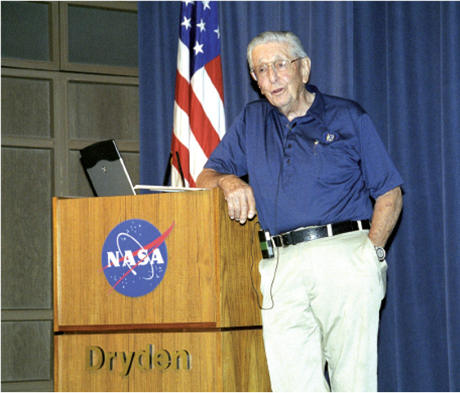

Those pilots privileged to know Scott

Crossfield regarded him as one of

aviation’s most durable good guys.

In a career that spanned some six decades,

Scotty flew a little of everything, from the

Wright Flyer to the X-15, and he somehow

managed to survive them all.

Sadly,we lost Scott Crossfield in April

2006 to an inflight breakup in a Georgia

thunderstorm, but not before he initiated

development of the Crossfield Edition

engine. Scotty lived every day of his 84

years, and much of that time was spent

flying the world’s most exotic rocket

planes. At one point in the late 1950s,

Crossfield hadmore rocket time than any

other test pilot on Earth.

Scotty was more than just a talented test pilot, however. In his own words, he was first

and foremost an engineer,

and he regarded his flight

test talents as secondary.

Crossfield flew the X-1, X-4, X-5, XF-92, D-558-I and

D-558-II before transitioning to the ultimate rocket research plane, the X-15.

Having flown at ridiculous speeds and

altitudes (Scotty was the first man to exceed

Mach 2.0 and the first to survive flying faster thanMach 3.0),Crossfield knew that everything from guitar strings, golf clubs and shotgun barrels to NASA test

aircraft and spacecraft have been treated

cryogenically to harden them for the rigors

of their respective disciplines.

In the case of spacecraft, cryogenic

treatment helps guard against high speeds,

low pressure, high/low temperatures and

other rigors of high altitude flight. Why

couldn’t piston aircraft engines benefit

from the same process?

EnterVictor Sloan ofVictor Engines in

PaloAlto, California.Victor has been providing

some of the world’s most highly

regarded, balanced, blueprinted piston mills for more than 30 years, with some

customers even having their airplanes

flown in from Europe for installation.

Crossfield had flown behind a Victor

Black Edition engine in his Cessna 210A

for several years. The engineer had great

respect forVictor and felt a collaboration

could produce a truly durable powerplant.

Of course, the first question is why

cryogenics? If Crossfield was an expert on the subject,Victor wasn’t unfamiliar with the concept. An avid motorcycle

racer in his younger days, Sloan was conversant

with most of the go-fast techniques

in bike and auto racing, and he

knew that NASCAR and NHRA teams

had long been experimenting with cryogenic

treatment to toughen brake and

suspension systems, two of the most

abused components in racing.

OK, so what exactly is cryogenic tempering?

Cryogenic temperatures are typ- ically those below -244 degrees F, well

below mere “cold” treatment that demands

only -125 degrees F. A typical

cryogenic cycle includes placing the parts

in an airtight cryonic chamber, gradually

lowering the temperature using nitrogen,

holding at -300 degrees F and then

slowly returning the parts to room temperature.

In some cases, a short tempering

cycle completes the process. Cryogenic

treatment typically requires 48 hours, 12

hours to bring the metal parts down to

the proper temperature, 24 hours to cure

and another 12 hours to bring them back

to roomtemperature. It can demand up to

70 hours, depending upon the composition

and amount ofmaterial to be treated.

The result of the treatment is a remarkable

transformation of the molecular

structure of the parts. In addition to

relieving residual stresses within the

metal and hardening the material exponentially,

it’s suspected of actually refining

and realigning the crystalline structure of

the metal.

The bottom line is a level of hardness otherwise uncommon in the engine overhaul

business. An engine consists of a

number of components, so toughermetal

components alone are no guarantee

against problems, but the cryogenic

process definitely does harden the target. The bottom line is a level of hardness otherwise uncommon in the engine overhaul

business. An engine consists of a

number of components, so toughermetal

components alone are no guarantee

against problems, but the cryogenic

process definitely does harden the target.

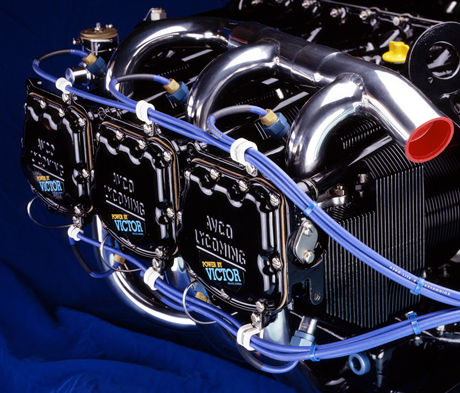

Accordingly,Victor selected the most

complex and powerful flat engine in general

aviation, a Lycoming IO-720-A1A, as

his test article for the Crossfield Edition

cryogenic application. In general aviation

terms, the 400 hp Lycoming is the peak of

the pyramid with a flat engine. (There are

a number of round engines with seven or

more cylinders that produce more horsepower,

but none remain in production. In

themid-‘60s,Lycoming introduced the IO-720 as the ultimate piston mill, and even

today, it’s the most powerful horizontally opposed

powerplant available.)

For better or worse, the only production

airplane to use the King Kong Lycoming

was the PA-24 Comanche,

perhaps the most hard core Piper ever to

wear an N-number. There are a number

of conversions – Aero Commander, Beech Queen Air – but Ted Smith

Aerostar was the only other manufacture

to experiment with a production model

800 that would have featured twin IO-720s. Smith dropped the project.

Ultimate speed and performance

were the goals for the Comanche 400.

The original Comanches of the mid-‘60s

were wide, comfortable machines, blessed

with pleasant handling, a docile stall

and reasonable economy. Despite what

youmay have heard about the invincible

V-tail Bonanzas, the 250 and 260 hp Comanches

weren’t that far behind the

Beech or the Bellanca 260, and they were

about even with the four-seat Cessna

210. In the early 60s, all four airplanes

used 260 hp engines to cruise in the 160-170 knot range.

No big surprise, then, that Piper

elected to up the ante on the Comanche

by employing weapons grade horsepower.

In 1964, Pipermounted themonster, eight-cylinder, Lycoming on the

nose of a Comanche to create the Comanche

400, producing what was, at the

time, the fastest normally-aspirated roduction

single in the world.

Though the king-sized engine is definitely

more than a pair of four-cylinder,

200 hp, IO-360s welded together, it does

offer a total of 720 cubic inches of displacement

and 400 hp. Trouble is, more

cylinders and horsepower are supposed

to be anathema to reliability. Increase the

number ofmoving parts inside an engine

by 33 percent and you’ll nearly always

lower TBO and increase the incidence of

premature failure.

Piper incorporated a number of

changes to handle the big engine on the

Comanche airframe. Most prominently,

the tail was modified to increase rudder

and elevator authority.There’s essentially

no commonality between the empennage

on the lesser-powered Comanches

and the 400.

The additional power also dictates

that the 400’s rudder be aerodynamically

balanced in a manner similar to that of

theTwin Comanche.Also, the Comanche

400 doesn’t employ the lead external balance

weights of the lower-powered single-engine Comanches. The additional power also dictates

that the 400’s rudder be aerodynamically

balanced in a manner similar to that of

theTwin Comanche.Also, the Comanche

400 doesn’t employ the lead external balance

weights of the lower-powered single-engine Comanches.

Conversely, all the Comanche’s fly

above the same 36 foot span airfoil. The

Comanche 400’s fuselage is a foot longer than the original Comanche 180s, but the

airplanes have a startling resemblance

parked side-by-side on the ramp.

Victor went looking for a Comanche

400 demonstrator for the Crossfield Edition

engine and found one in the Midwest.

A farmer in DesMoines, Iowa had

a reasonably nice 400 parked in a barn

adjacent to his private grass strip,Victor

purchased it as was, relicensed it and flew

it to California for a complete overhaul.

“The point of the Crossfield Edition

isn’t necessarily more power,” Victor

comments. “You can’t legally produce

more than rated power, anyway. But the

exhaust system and all the accessories

drain away some power, so we wanted

an engine that would deliver the maximum allowable

horsepower to the prop.”

At a gross weight of 3600 pounds and

with 400 horsepower on tap, the airplane

enjoys a power loading of 9.0 pounds per

horsepower, the lowest of any general aviation, production airplane outside the

aerobatic category. Power loading isn’t

the only measure of takeoff acceleration,

but it’s one of the most important.

Flying fromVictor Engine’s home base

of Palo Alto, California,with Sloan in the

right seat and Pilot Peggy in back, the

Comanche 400 left little doubt that it was

not your grandfather’s Comanche. To fly

the finished Crossfield Edition demonstrator

is to experience what seems a

gradual tsunami of thrust.

Push the left knob to the wall, and the

engine pulls like a team of rabid Malamutes.

It’s not exactly the same as dropping

the clutch on a ZR1, but among

four-place, cross country airplanes, it’s an

experience you’re not liable to match.

Perhaps contrary to what you might

expect, however, the Crossfield Comanche

doesn’t feel drunk with power.

Acceleration does seem to go on and on

as the Comanche seizes the bit in its teeth and inhales altitude with enthusiasm, but

the Comanche 400 is easily manageable

in the pattern.

In keeping with the airplane’s considerable

power, I used about 120 knots cruise climb and still scored an initial

1400 fpm uphill as we cleared the class B

airspace to the west of Palo Alto and

lofted out over the coastal hills into unrestricted

airspace.

I saw 10,500 feet on the altimeter in a

little under nine minutes.This is one airplane

that’s not dependent on a turbocharger

for reasonable climb.The book

spec for service ceiling suggests

19,500 feet, so there’s plenty left at a

typical cruise height.

The big question, of course, is cruise

performance. The book number for 75

percent is 185 knots at 8000 feet. In 1964,

that made the PA-24-400 the world’s

fastest normally-aspirated production

single. Victor’s Crossfield Edition Comanche

generated more like 190 knots

on the same power, though with only 40

hours on the tach, the new mill was just

getting broken in. Sloan is confident he’ll

see another two or three knots of speed

when the engine is running at optimum.

An obvious benefit is that the Crossfield

Comanche can generate the same horsepower

at higher altitude, so better speed

is almost a given in the thinner air.

Remember, however, that 75 percent

of 400 hp is still 300 hp. Specific fuel consumption

is fairly immutable, about .43

pounds/hp/hr. Do the math, and the result

is about 22 gph, so the top Comanche

isn’t liable to win favor with the

Sierra Club.Thatmeans the standard airplane’s

100 gallon tanks are worth about

3+30 plus reserve. Tip tanks can add 15

gallons a side for a total of 130, worth

about five hours endurance atmax cruise.

As this is written, the Crossfield Edition

Cryogenic Engine has seen less than

100 hours use in Victor Aviation’s Comanche

400. Standard TBO is listed as

1800 hours.With the benefit of cryogenic

tempering, logic suggests it should last

considerably longer than that, perhaps

well over 2000 hours.

If I’m still here when that time comes,

I’ll keep you informed.

Back |