| Ultrasonic EMAT Inspection |

|

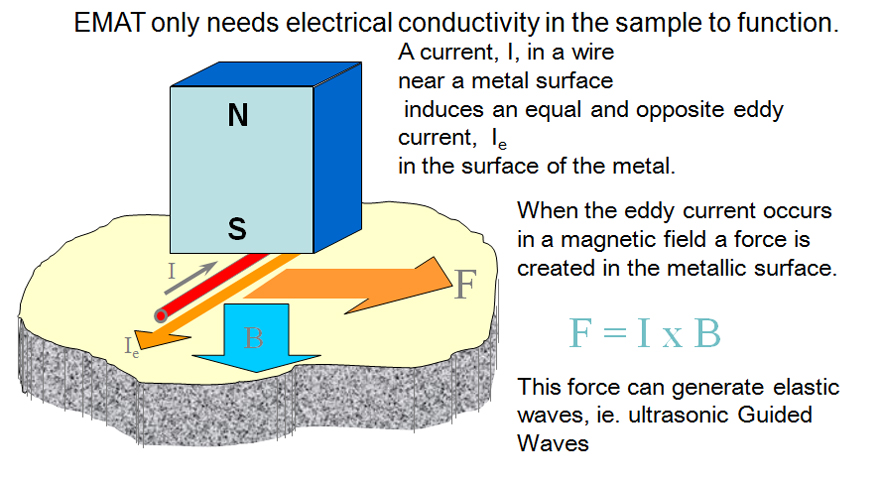

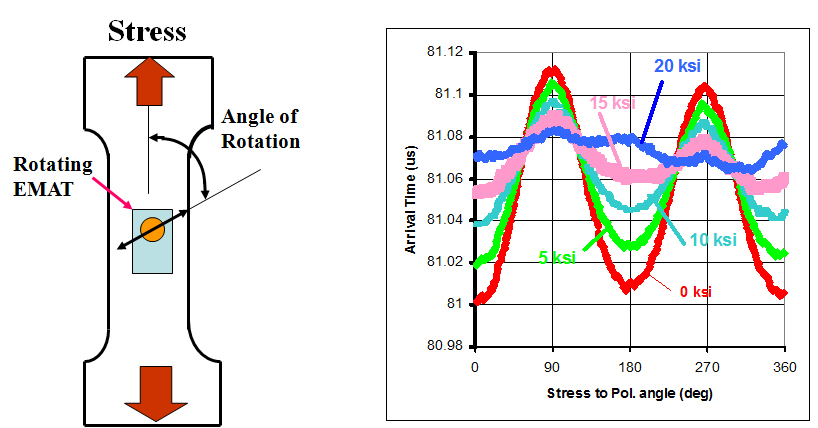

Electromagnetic Acoustic Transmission (EMAT)

The most important application of EMATs has been in nondestructive evaluation (NDE) applications such as flaw detection or material property characterization. Couplant free transduction allows operation without contact at elevated and cryogenic temperatures. Evaluation of materials that have been welded, heat treated or formed often require a method to determine grain orientation, elongation and comparative residual stress measurements. These tests can be performed in the field at ambient temperature or in our laboratory real-time from –300F to +350F in a cryogenic/heat chamber.

The coil and magnet structure can also be designed to excite complex wave patterns and polarizations that would be difficult to realize with fluid coupled piezoelectric probes. In the inference of material properties from precise velocity or attenuation measurements, using EMATs can eliminate errors associated with couplant variation, particularly in contact measurements.

|

| Carbon Composite Brakes C-Scan Testing |

|

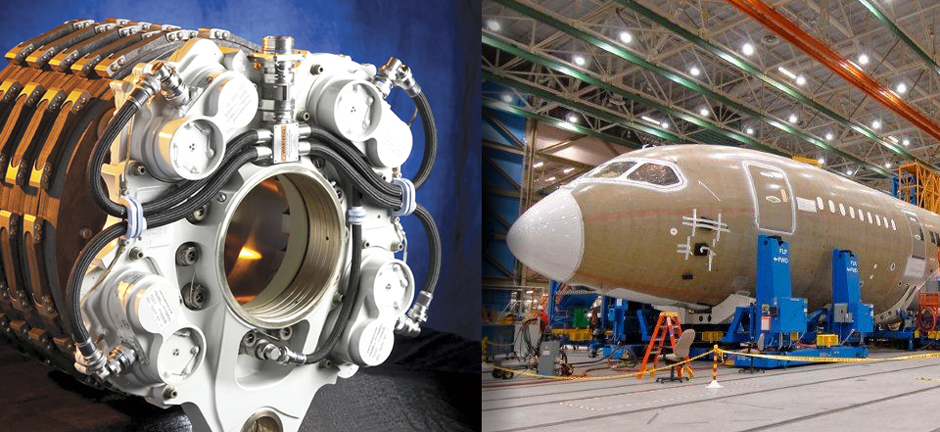

| Carbon Composite Brakes |

Boeing Aircraft |

|

|

|

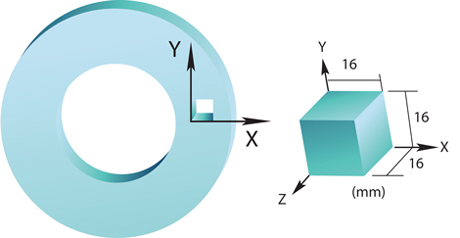

| COMPOSITE ROTOR BRAKE DISK AND SAMPLE SECTION |

|

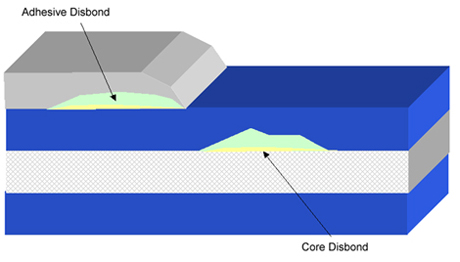

CROSS SECTION OF CARBON COMPOSITE MATERIAL |

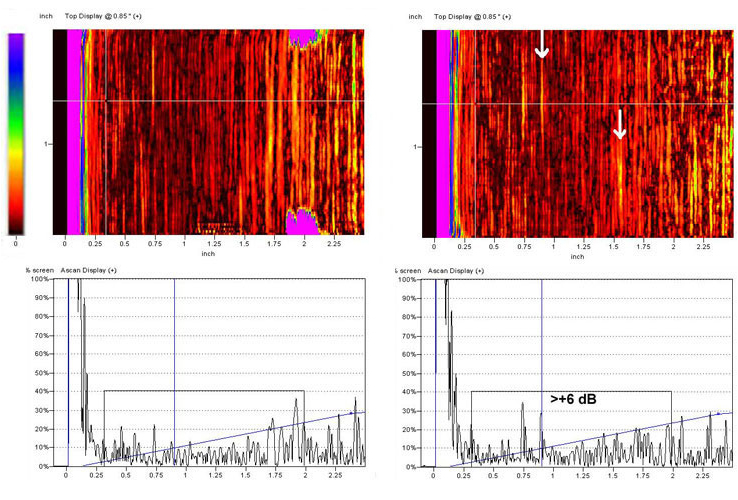

Immersion Ultrasound

C-Scans (Top)

A-Scan (Bottom)

Carbon Composites

By measuring the before and after ultrasonic wave velocities in three directional planes in immersion tests can also identify the characteristics of anisotropy. |

|

| |

Ultrasonic methods of non destructive testing use beams of mechanical waves of short wavelength and high frequency, transmitted from a probe and detected by the same or other probes. An oscilloscope display with a time base shows the time it takes for a ultrasonic pulse to travel to a reflector (a flaw, the back surface or other free surface) in terms of distance travelled across the oscilloscope screen. The height of the reflected pulse is related pulse is related to the flaw size as seen from the transmitter probe. The relationship of flaw size, distance and reflectivity are complex, and a considerable skill is required to interpret the display.

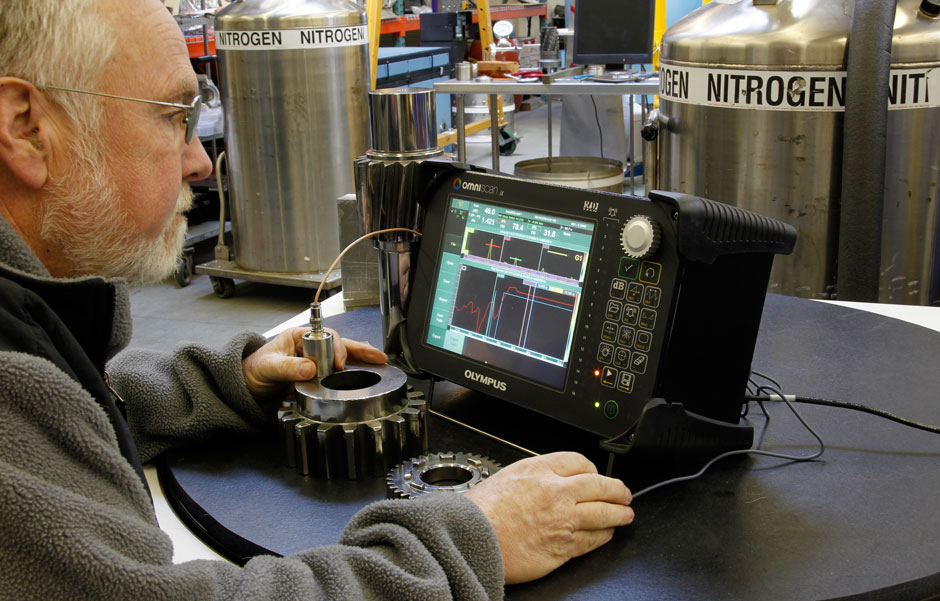

Ultrasonic examination is utilized as a non-destructive testing method to carry out a wide variety of testing tasks enabling Victor Aviation technicians to conduct internal material defect examinations and make measurements of a component. The testing process may be performed in an immersion tank or on the surface of the material to be examined using a couplant and piezoelectric sensors. For applications where a couplant is not desired we use electromagnetic acoustic transmission using EMAT sensors which require no couplant. |

|

|

| |

|

EMAT Sensor on NASA Wind Tunnel Turbine Blade |

| Electromagnetic Acoustic Transduction Principles |

|

The Lorentz Force

The flow of an electric current down a conducting wire is ultimately due to the motion of electrically charged particles (in most cases, electrons) through the conducting medium. It seems reasonable, therefore, that the force exerted on the wire when it is placed in a magnetic field is really the resultant of the forces exerted on these moving charges. |

|

|

| EMAT BIREFRINGENCE TESTING |

|

| |

|

| |

|

| EMAT SENSORS INSTALLED ON A WIND TURBINE TRANSMISSION GEAR |

|